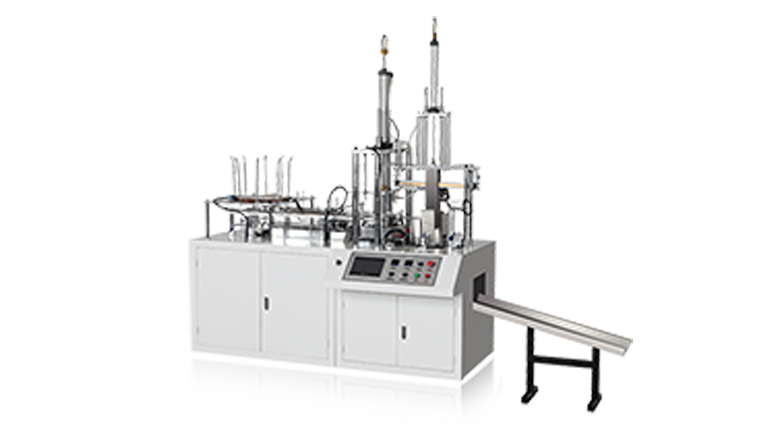

Fully automatic intelligent cake paper cup molding machine

The rated speed of the Equipment is 50 times/ min, the current fastest speed of this type machine is 60 times/ min, it has material monitoring, feeding monitoring, forming monitoring collection monitoring and other automatic systems, if machine appears running fault, systems will stop the machine with the alarm.

Belongs to automatic paper products molding equipment, speed fast, easy to operate and so on. This model uses hot air generating device system, suitable for single PE coated paper. Fast Speed, energy saving, stability, simple operation, microcomputer testing, the domestic advanced technology products.

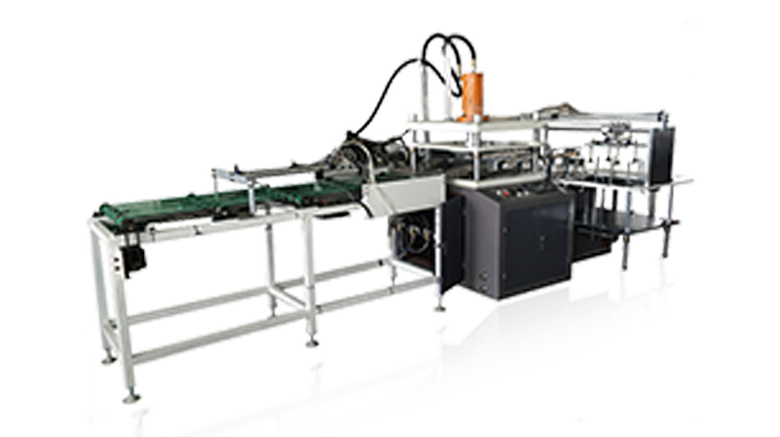

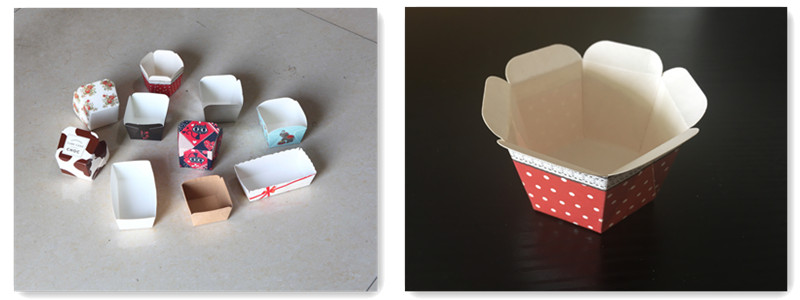

Automatic feeding, heating(with hot air generating device) hot molding (four corners of adhesive lunch box), automatic point and collection, microcomputer control and other continuous processes, for the production of single-piece disposable paper lunch boxes, paper lunch boxes, cake cups, food package boxes and so on.

WANT QUOTE & SOLUTION NOW?

Leave us a messgae and we’ll get back to you as quickly as possible